WillDAQ,

It's a concept design, not production, so patents don't matter.

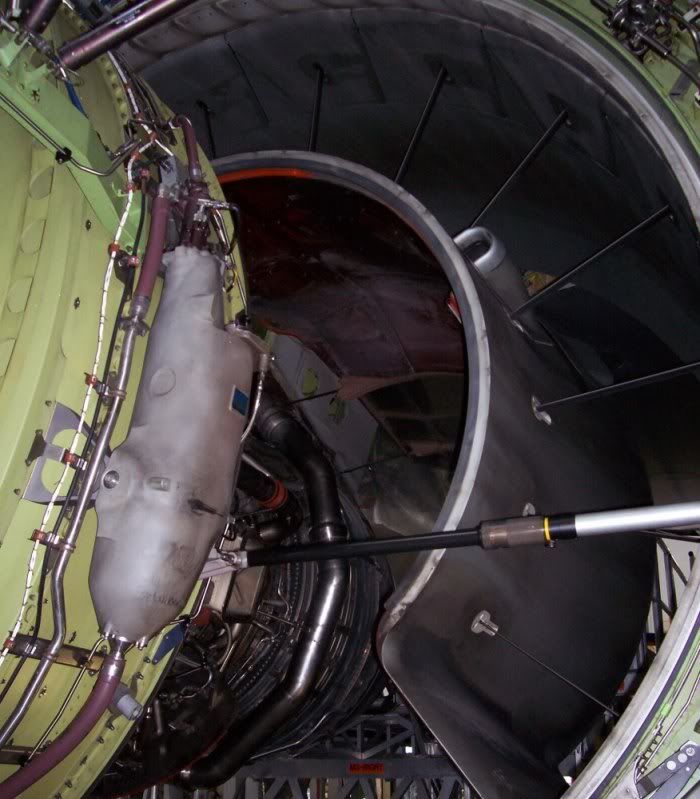

The engine access could be done easily if the wing was made to hold the mechanic, it would be easily accessed for maintenance.

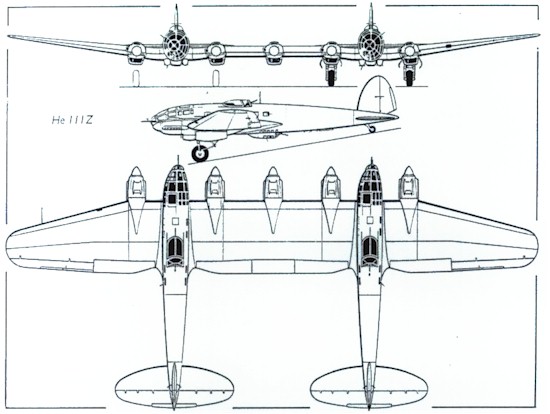

The Honda Jet's wing is close to the ground, it doesn't mean the delta has to be that low, actually, that's an interesting idea. What about a high delta wing with a low-slung engine and a low and forward canard? You think the canard that far forward would screw up the lift at certain angles of attack?

I still like the idea of the delta and canard to make a nice roomy cabin and a large baggage hold without having to drop the wing low like in the Honda or some of the Leers.

As for awesome aircraft:

https://pic.armedcats.net/b/bl/blind_io/2009/08/14/DeltaAirlinesDc3_1.jpg

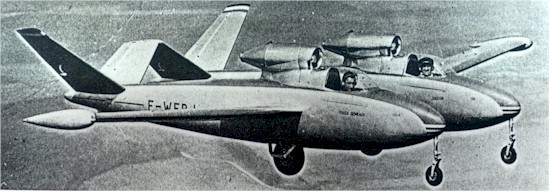

I have actually been aboard this plane (not in flight, unfortunately). This is actually Delta's first aircraft. It was taken over by the government for WWII then returned to Delta where it went back into service. It was finally sold and forgotten. Years later Delta decided to find the plane, expecting it to be in a boneyard, they tracked it down in South America where it was still flying cargo. It had over 1 million flight hours on the airframe. Delta flew it back to the US (with every warning light on, according to the pilot I spoke to) and it was fully restored, complete with custom dyed and woven carpet and seat covers to make it original. The attention to detail is amazing, they spent over a year looking for the phone cord for the aft galley phone.

Here are a couple photos I took when I saw this aircraft. Sorry if they look crooked, it's from the scanning:

https://pic.armedcats.net/b/bl/blind_io/2009/08/14/911852619_l.jpg

https://pic.armedcats.net/b/bl/blind_io/2009/08/14/911852859_l.jpg

https://pic.armedcats.net/b/bl/blind_io/2009/08/14/911852955_l.jpg

It's a concept design, not production, so patents don't matter.

The engine access could be done easily if the wing was made to hold the mechanic, it would be easily accessed for maintenance.

The Honda Jet's wing is close to the ground, it doesn't mean the delta has to be that low, actually, that's an interesting idea. What about a high delta wing with a low-slung engine and a low and forward canard? You think the canard that far forward would screw up the lift at certain angles of attack?

I still like the idea of the delta and canard to make a nice roomy cabin and a large baggage hold without having to drop the wing low like in the Honda or some of the Leers.

As for awesome aircraft:

https://pic.armedcats.net/b/bl/blind_io/2009/08/14/DeltaAirlinesDc3_1.jpg

I have actually been aboard this plane (not in flight, unfortunately). This is actually Delta's first aircraft. It was taken over by the government for WWII then returned to Delta where it went back into service. It was finally sold and forgotten. Years later Delta decided to find the plane, expecting it to be in a boneyard, they tracked it down in South America where it was still flying cargo. It had over 1 million flight hours on the airframe. Delta flew it back to the US (with every warning light on, according to the pilot I spoke to) and it was fully restored, complete with custom dyed and woven carpet and seat covers to make it original. The attention to detail is amazing, they spent over a year looking for the phone cord for the aft galley phone.

Here are a couple photos I took when I saw this aircraft. Sorry if they look crooked, it's from the scanning:

https://pic.armedcats.net/b/bl/blind_io/2009/08/14/911852619_l.jpg

https://pic.armedcats.net/b/bl/blind_io/2009/08/14/911852859_l.jpg

https://pic.armedcats.net/b/bl/blind_io/2009/08/14/911852955_l.jpg