You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My 89 Merkur XR4Ti

- Thread starter airmenair

- Start date

airmenair

Well-Known Member

I've heard that before. I'm guessing you are talking about my stuck crank bolt? Well I already got it off.

airmenair

Well-Known Member

Last night I spent all my energy undoing a stupid thing I did when I was trying to put the timing belt on. I thought it would be a good idea to put the crank pulley on to aid in getting the engine to TDC. Well it didn't really help and it ended up getting stuck on. I rented a 3 Jaw gear puller and after fiddling with it, injuring myself and alot of cursing I got the thing off finally at around 9:30 last night.

This is mostly a question for CraigB (although anyone feel free to chime in) since he has the same engine but is there a trick to putting the timing belt on? Each time I line up all the corresponding pulleys to their locations I end up getting too much slack on the untensioned side of the belt so when I go to rotate the crank either the belt slips or there is so much play in the belt that the crank rotates a few degrees before the slack is taken up and thus the idler pulley and cam pulley do not start rotating immediately with the crank. After two turns to get it back to TDC the neither the cam pulley or the distributor rotor are in the place they need to be. Suggestions?

This is mostly a question for CraigB (although anyone feel free to chime in) since he has the same engine but is there a trick to putting the timing belt on? Each time I line up all the corresponding pulleys to their locations I end up getting too much slack on the untensioned side of the belt so when I go to rotate the crank either the belt slips or there is so much play in the belt that the crank rotates a few degrees before the slack is taken up and thus the idler pulley and cam pulley do not start rotating immediately with the crank. After two turns to get it back to TDC the neither the cam pulley or the distributor rotor are in the place they need to be. Suggestions?

- Joined

- Feb 14, 2007

- Messages

- 17,850

- Location

- SWMO

- Car(s)

- Mustang SVO - Frontier Pro-4X - BRZ - D21 Hardbody

This is mostly a question for CraigB (although anyone feel free to chime in) since he has the same engine but is there a trick to putting the timing belt on? Each time I line up all the corresponding pulleys to their locations I end up getting too much slack on the untensioned side of the belt so when I go to rotate the crank either the belt slips or there is so much play in the belt that the crank rotates a few degrees before the slack is taken up and thus the idler pulley and cam pulley do not start rotating immediately with the crank. After two turns to get it back to TDC the neither the cam pulley or the distributor rotor are in the place they need to be. Suggestions?

I've only installed a timing belt on my car once. I pulled the distributor and restabbed it after I got the timing belt timed. Other than that, is there anyway to get the slack out of the untensioned side, before you tension it?

airmenair

Well-Known Member

I've only installed a timing belt on my car once. I pulled the distributor and restabbed it after I got the timing belt timed. Other than that, is there anyway to get the slack out of the untensioned side, before you tension it?

Hmm I hadn't thought about. I might try it that way. Each time I try an put the belt on I find that I'm about 1 tooth off on the cam pulley. If I could stretch the belt about 1 tooth I would be able to get it on with no slack. This is tough by hand haha.

Airmenair, can you provide pictures?

I haven't been around the car all weekend but I'll post some tomorrow evening if necessary.

airmenair

Well-Known Member

Ok I fiddled again with it today and had success. I think I had the crank and cam slightly misaligned which contributed to the slackness. However, I need to adjust the distributor. I can't for the life of me figure out where the hold down bolt/nut is. The shop manual wasn't much help either. Any help with it would be much appreciated although describing where a bolt is in words is a bit tough. A picture is worth a thousand words they say

And yes argatoga the 302 has a nice and accessible hold down bolt

And yes argatoga the 302 has a nice and accessible hold down bolt

- Joined

- Feb 14, 2007

- Messages

- 17,850

- Location

- SWMO

- Car(s)

- Mustang SVO - Frontier Pro-4X - BRZ - D21 Hardbody

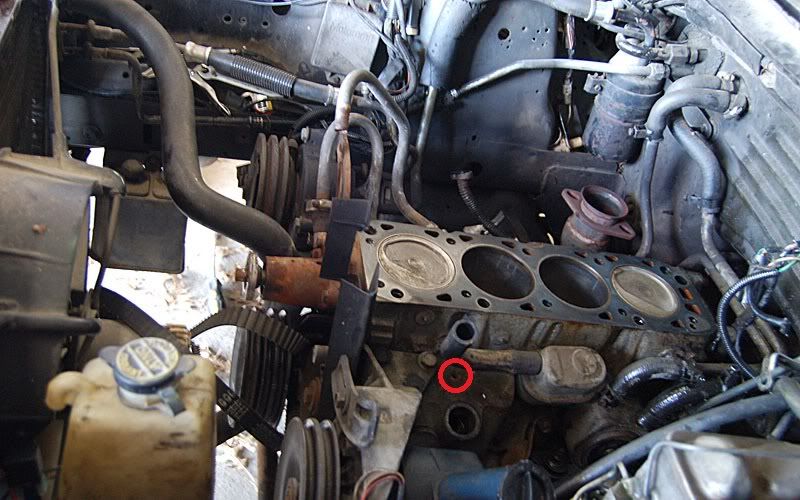

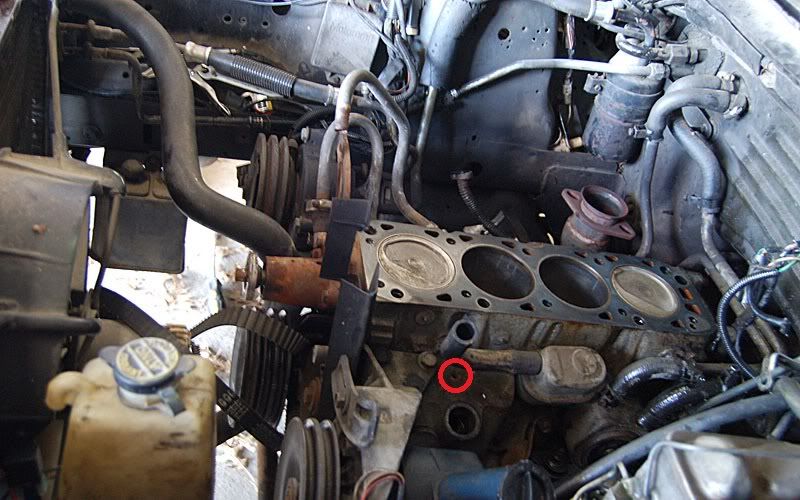

https://pic.armedcats.net/c/cr/craigb/2009/02/23/blown_hg2.jpg

The distributor hold down bolt is between the block and the distributor (its the rusty hole in the photo above, just below the PCV hose).

The distributor hold down bolt is between the block and the distributor (its the rusty hole in the photo above, just below the PCV hose).

airmenair

Well-Known Member

Cool thanks. It's the hole I've circled in red?

Off hand do you know the size? Maybe a 13mm?

Off hand do you know the size? Maybe a 13mm?

airmenair

Well-Known Member

It turned out to be a 17mm. Took me about 15 minutes just find the right angle in order to actually get the wrench in to loosen that blasted bolt. I have no idea how you got a socket on there, I tried and tried and just gave up :lol:

So now that that is taken care of the list of tasks are as follows

- Reattach crank pulley and install drive belts and outer timing cover

- Install valve cover

- Install upper intake and throttle body

- Attach turbo the throttle body

- Attach intake to turbo

- Install radiator and fan

- Reattach all cooling lines, replace where necessary, fill with coolant

- Add oil and replace oil filter

- Replace battery

- Replace spark plugs

- Hook up all remaining loose connections, wires, hoses, etc

- Drain Tank

Draining the tank is going to be a real pain. Shortly (like 15 miles) before I blew the headgasket, I filled up the tank (about 14 gallons). So I have 14ish gallons of gas I need to drain . Anyone got some tips on this? Like what on earth to drain it into?

. Anyone got some tips on this? Like what on earth to drain it into?

The order I listed them is the order I plan to do the tasks. What other idiot tests should I do before turning the key?

So now that that is taken care of the list of tasks are as follows

- Reattach crank pulley and install drive belts and outer timing cover

- Install valve cover

- Install upper intake and throttle body

- Attach turbo the throttle body

- Attach intake to turbo

- Install radiator and fan

- Reattach all cooling lines, replace where necessary, fill with coolant

- Add oil and replace oil filter

- Replace battery

- Replace spark plugs

- Hook up all remaining loose connections, wires, hoses, etc

- Drain Tank

Draining the tank is going to be a real pain. Shortly (like 15 miles) before I blew the headgasket, I filled up the tank (about 14 gallons). So I have 14ish gallons of gas I need to drain

. Anyone got some tips on this? Like what on earth to drain it into?

. Anyone got some tips on this? Like what on earth to drain it into?The order I listed them is the order I plan to do the tasks. What other idiot tests should I do before turning the key?

Spectre

The Deported

- Joined

- Feb 1, 2007

- Messages

- 36,832

- Location

- Dallas, Texas

- Car(s)

- 00 4Runner | 02 919 | 87 XJ6 | 86 CB700SC

Worse, it's 14 gallons of old gas.

Get four five gallon gas cans from Walmart. Disconnect the fuel feed line to the engine, route the hose into the first gas can. Apply power to the fuel pump, watch it fill the can. Let it get about 3/4-7/8 full and cut power to the pump. Swap out cans and repeat until tank is empty. It will probably have more than 14 gallons in it by the time it pumps dry, hence the four cans. This also goes easier if you have a second person manning the pump power.

Get four five gallon gas cans from Walmart. Disconnect the fuel feed line to the engine, route the hose into the first gas can. Apply power to the fuel pump, watch it fill the can. Let it get about 3/4-7/8 full and cut power to the pump. Swap out cans and repeat until tank is empty. It will probably have more than 14 gallons in it by the time it pumps dry, hence the four cans. This also goes easier if you have a second person manning the pump power.

airmenair

Well-Known Member

Yeah I'm not looking forward to that step. Is there any use for that gas? Is there any treatment that can be done to it? Should I just relegate it to lawn mower duty?

Posmo

I'm a piano until proven otherwise

- Joined

- Oct 5, 2007

- Messages

- 4,203

- Location

- Finland

- Car(s)

- '86 Sierra iS, '70 Cortina, '90 Sierra, '04 RS182

Yeah I'm not looking forward to that step. Is there any use for that gas? Is there any treatment that can be done to it? Should I just relegate it to lawn mower duty?

Lawnmower gas and for cleaning things..? 14 gal. should last you a while

airmenair

Well-Known Member

Spectre

The Deported

- Joined

- Feb 1, 2007

- Messages

- 36,832

- Location

- Dallas, Texas

- Car(s)

- 00 4Runner | 02 919 | 87 XJ6 | 86 CB700SC

I would relegate it to lawnmower duty... or you can bring it over and we can kill my cop car's biohazard carpet with fire.

airmenair

Well-Known Member

Maybe I should open a poll...

Maybe I should open a poll...