I noticed the other week that some of the new 3D printers have this fancy magnetic build platform that can be removed and is flexible, allowing the part to be easily peeled off. The Creality and Ender printers seem to be the ones, I don't have one of those but I wanted in.

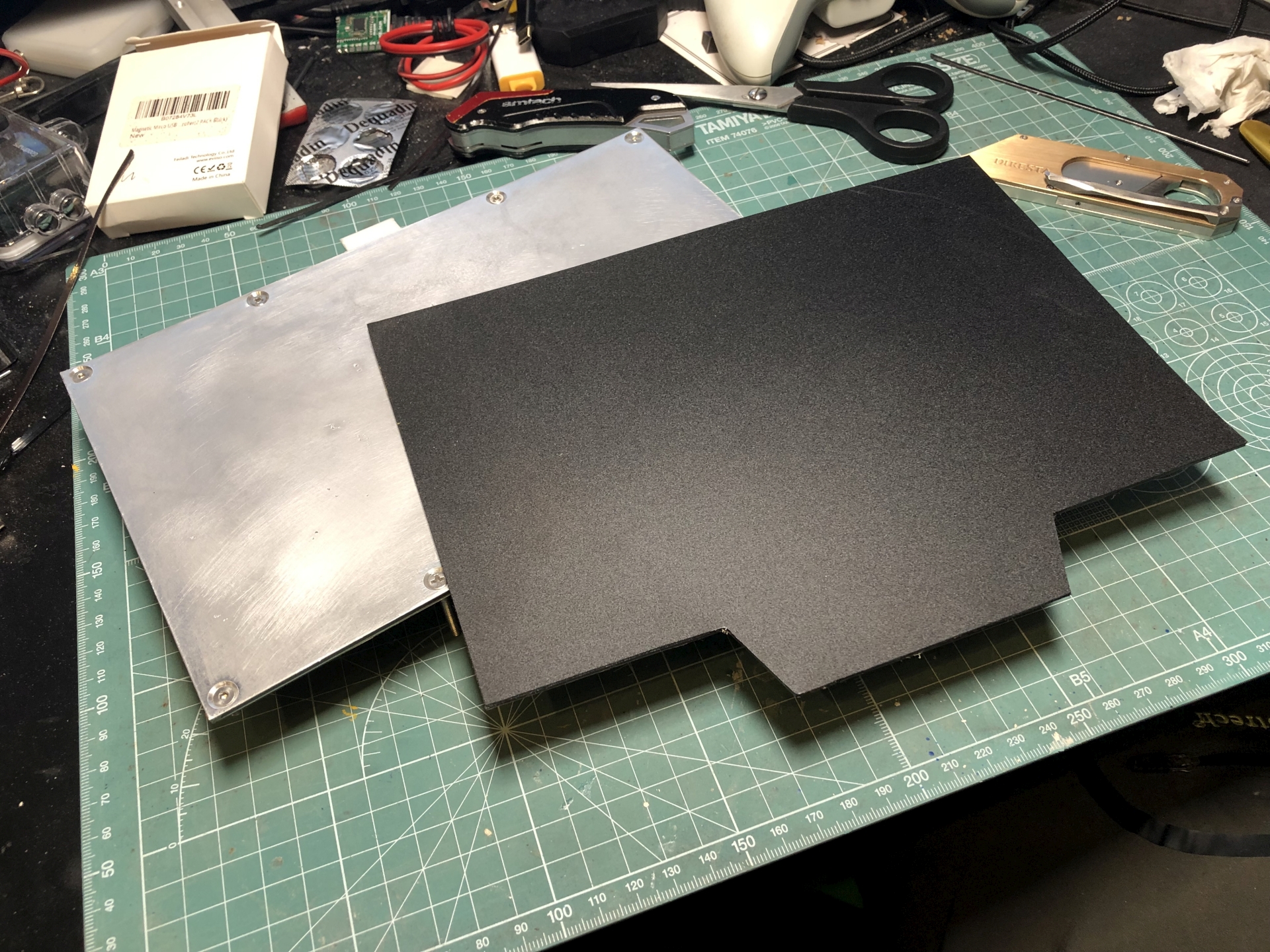

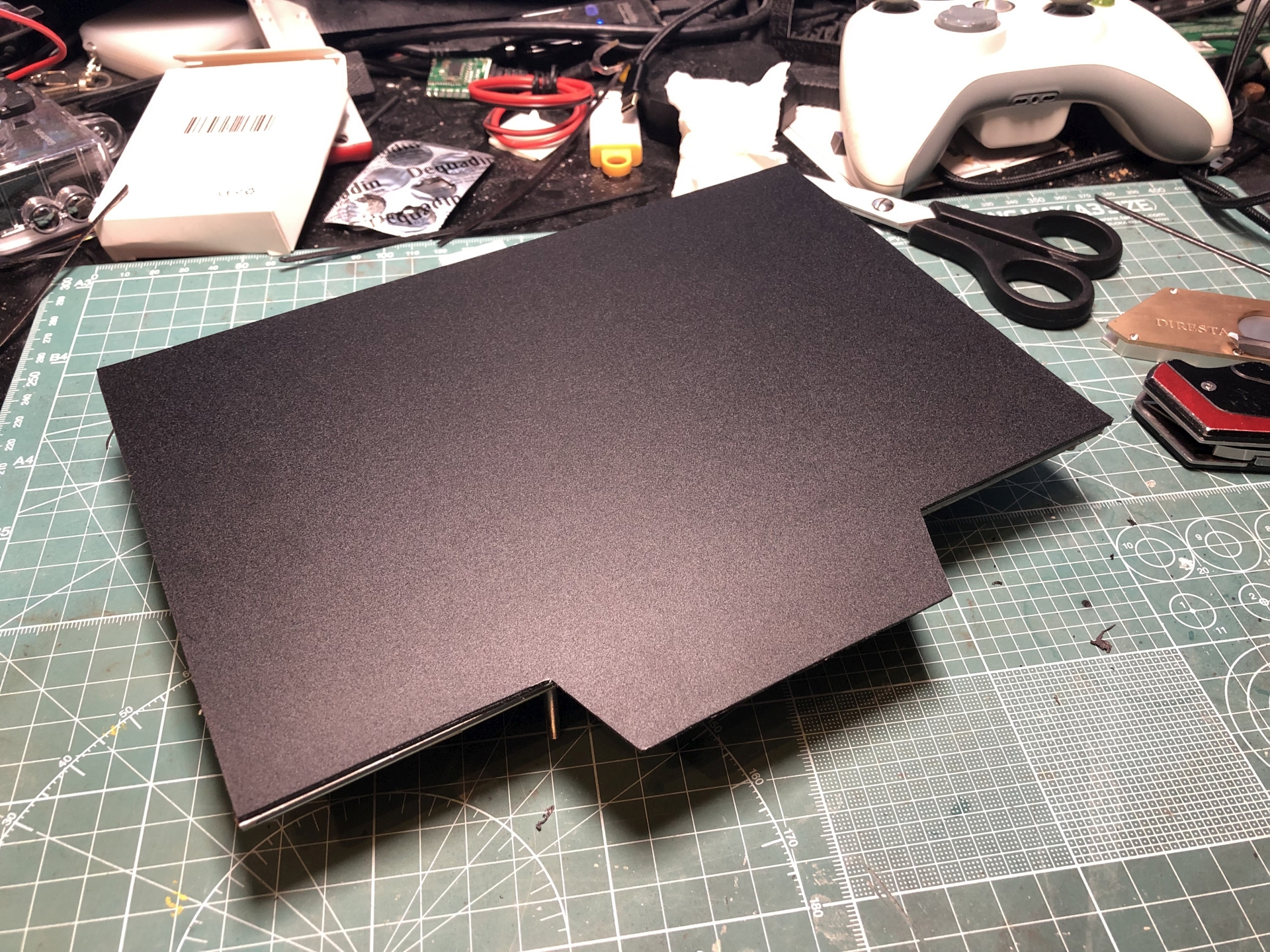

I bought the smallest I could get, 235x235mm, which was just a smidge larger than the 230mm bed width on my CTC. The length had to be cut down to 150mm and this allowed me to leave a lip to lift the material up by. This damn stuff was difficult to cut through.

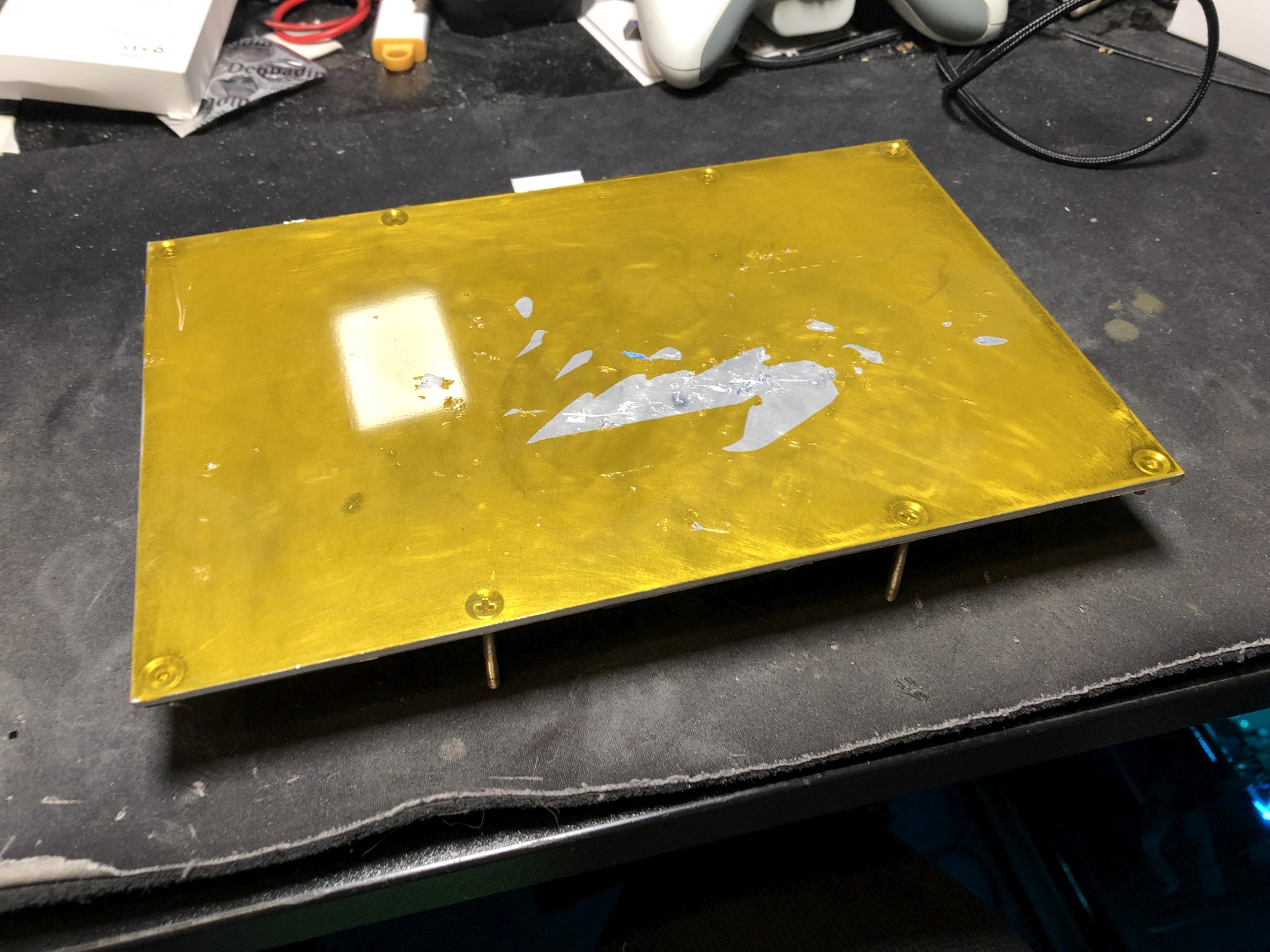

To prep the bed, first I had to peel off the blue tape and the kapton tape, damn stuff. This was well overdue for replacement but in reality I didn't have any issues arising from its neglect. This printer really is robust and now I've found a filament that works again (Athorbot changed their PLA and it became shit) I rarely get failed prints.

I scuffed up the aluminium surface to help the 3M VHB stick and then cleaned it up with IPA. There were some scratches from aggressive attempts to remove parts, I didn't try to get rid of these but just get rid of any sharp edges.

Stuck like shit to a blanket.

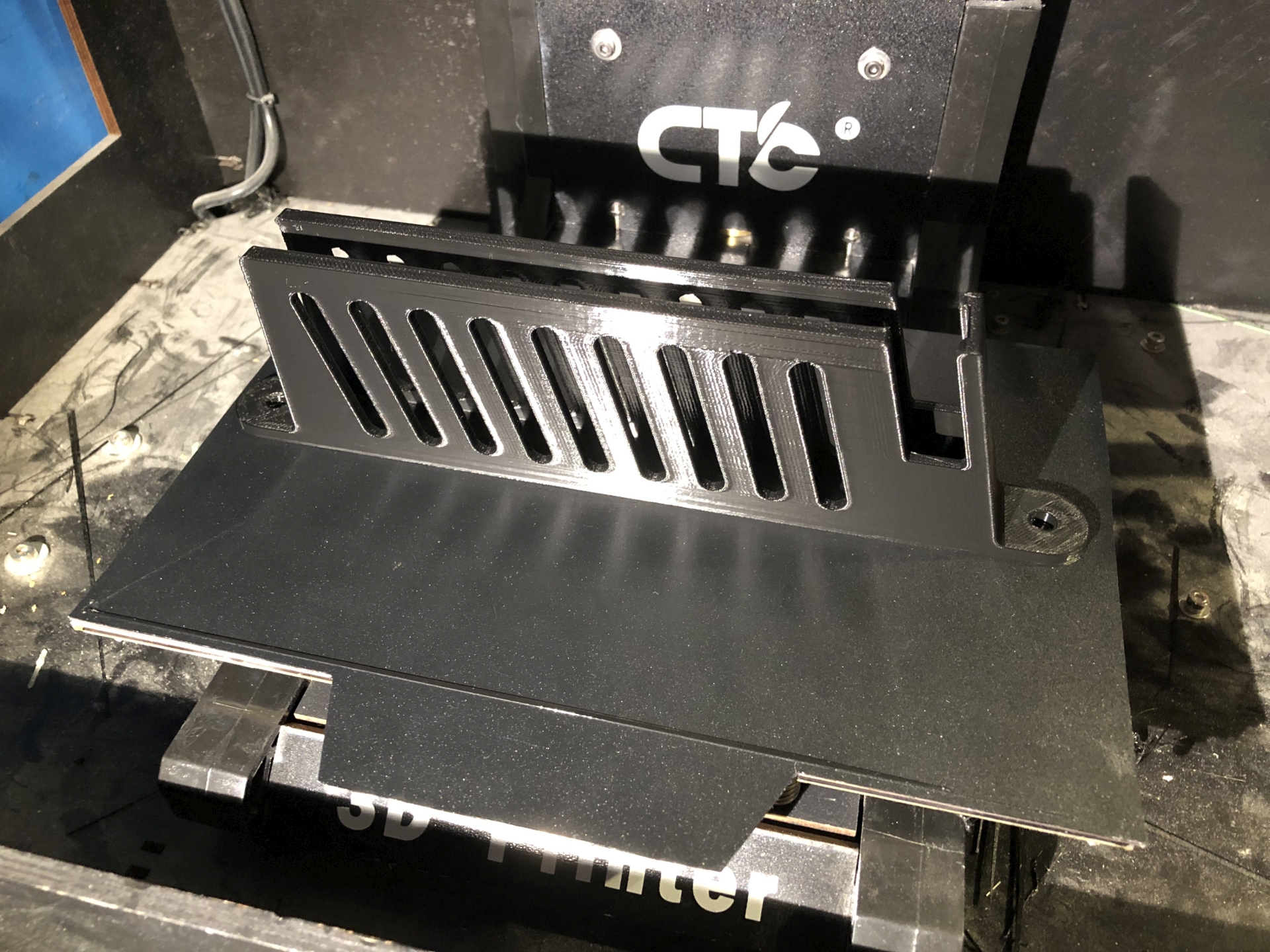

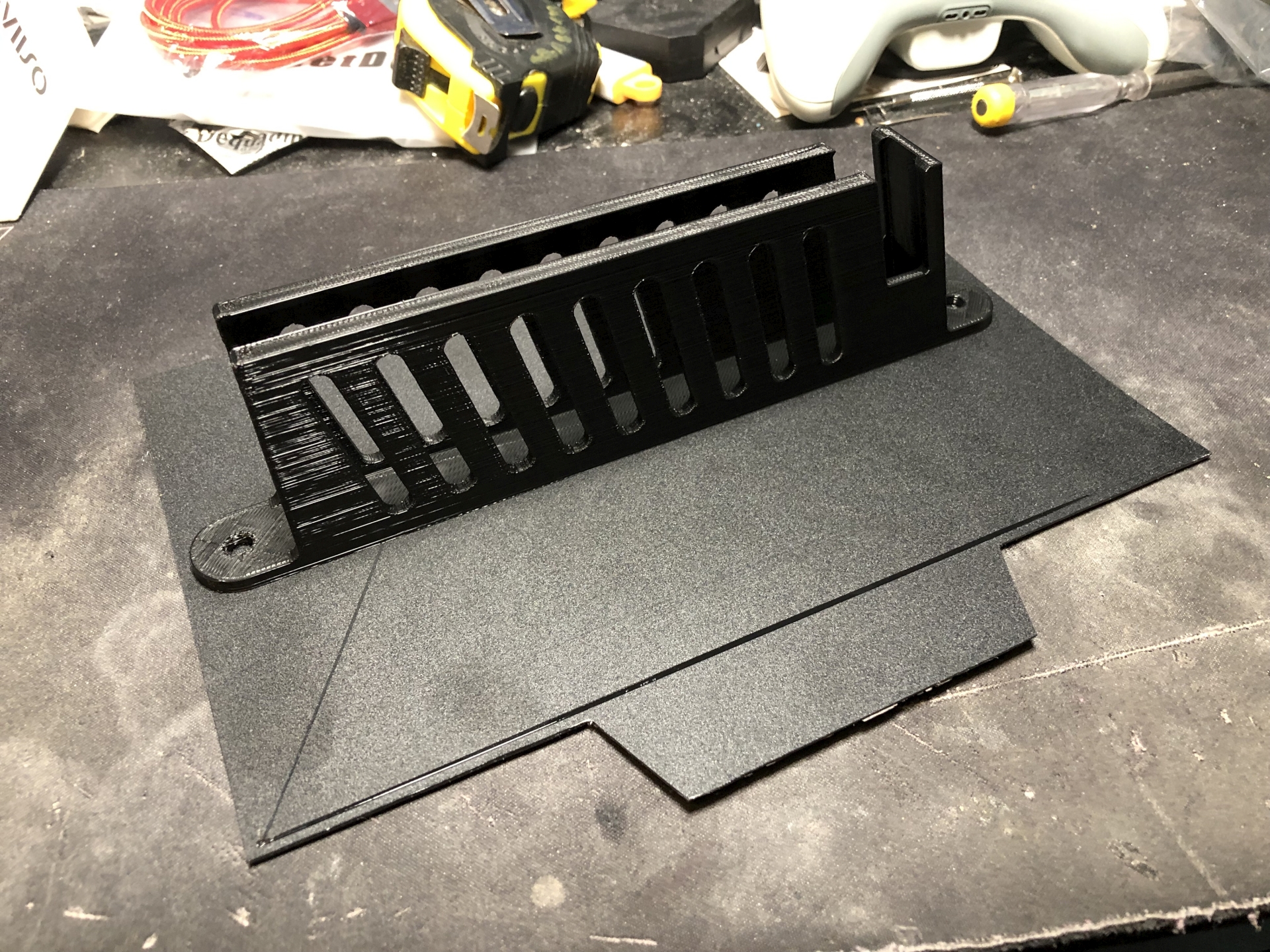

Did a print on it tonight, a AA battery holder for the pegboard. Nice to go from here... (yes that is dust around the printer, it doesn't get cleaned)

...to here without having to remove it from the print surface. Bending the material and peeling off the print was so satisfying and easy compared to the previous method of prying it off with a screwdriver.

As a bonus the material appears to hold the heat well, while the bed took a little bit longer to get up to temp it didn't need to be active anywhere near as much as it did before. That has to be a good thing, for the life of the heated bed if nothing else.